The first impression of a room isn't created on a screen, but in the workshop. Where the wood smells, edges are bent by hand, and the final sanding determines whether a surface is vibrant or merely shiny. This is precisely where the strength of Swiss craftsmanship for interiors lies: tangible precision and material culture that makes spaces calm, clear, and durable.

Why manufacturing quality changes spaces

Swiss workshops combine dimensional accuracy with an uncompromising eye for detail. A stair step feels solid, a drawer closes with gentle resistance, a tabletop sounds warm instead of hollow. This is no coincidence. It is the result of centuries-old skills, combined with modern tools and a keen sense of proportion.

The aesthetic lines are restrained and precise. Edge radii, shadow gaps, the way light moves across the grain—all of this is part of a design language that works without noise. It suits both minimalist floor plans and historic settings.

And it rarely gets loud. Good pieces allow themselves to be quiet.

Materials with origin

Regional resources shape the choice of materials, not only for ecological reasons, but also because of their tactile and acoustic qualities, which are crucial in interior spaces.

- Wood from sustainable forestry, often air-dried, provides structure and temperature.

- Natural stone from alpine quarries brings weight, robustness and a subtle color.

- Metal sets precise lines, serves as a supporting structure and as a subtle accent.

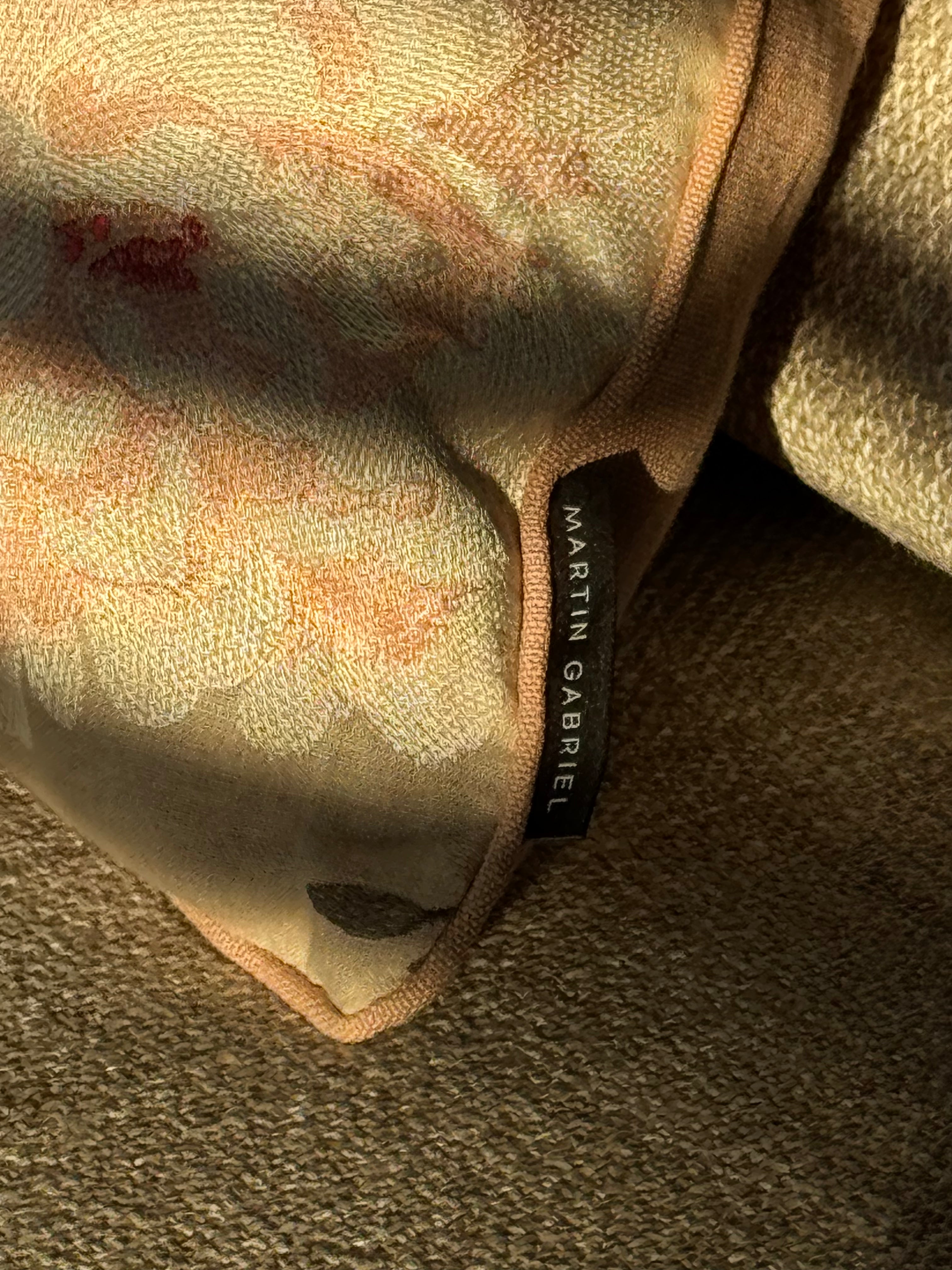

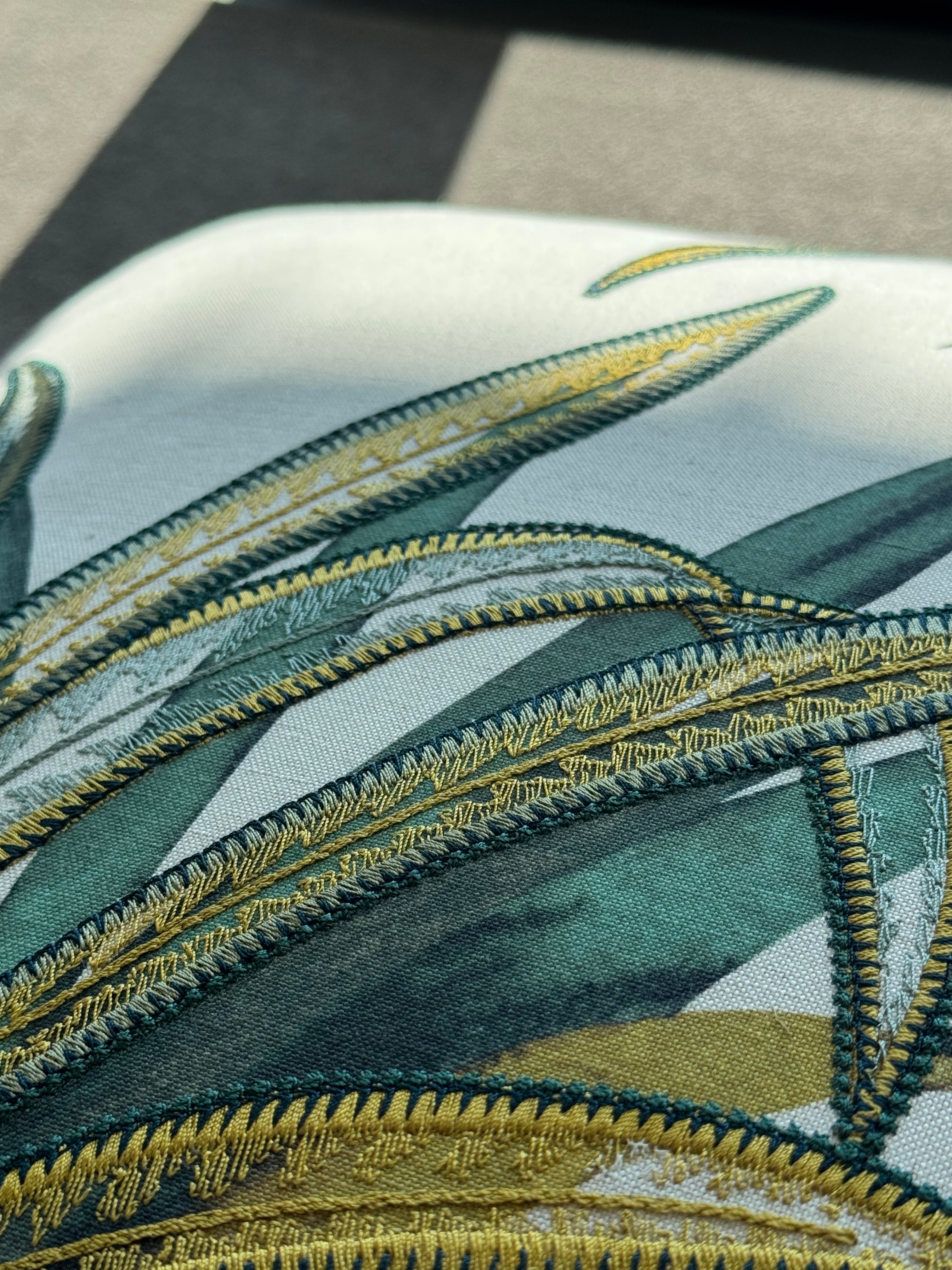

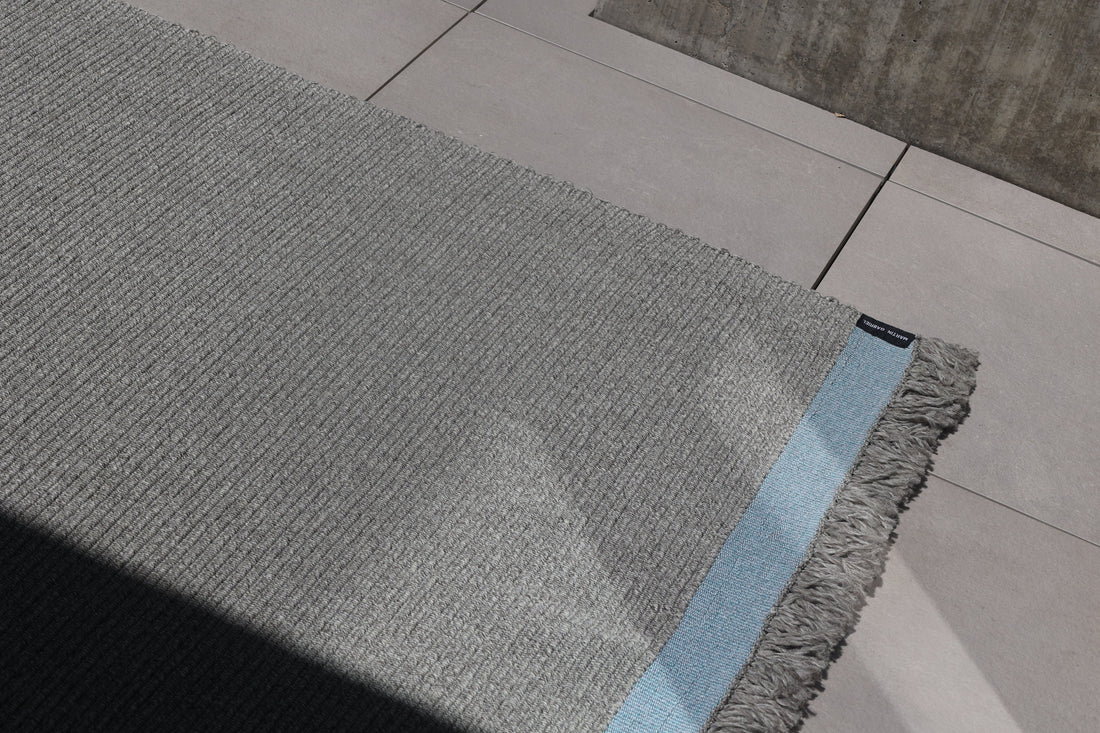

- Textiles made of wool or linen create zones and improve room acoustics.

- Glass and ceramics characterize light guidance and ease of care.

A compact overview:

| material | Origin/Region | Characteristics | Use in interior |

|---|---|---|---|

| oak | Central Plateau, Prealps | tough, open-pored, warm | Table tops, floors, kitchen fronts |

| walnut | Western Switzerland, selective import | fine-pored, lively grain | Accent furniture, wall paneling |

| larch | Alpine region | resinous, robust, reddish tone | Interior facades, windows, floors |

| Swiss stone pine | Graubünden, Valais | fragrant, soft, calming effect | bedroom furniture, wall paneling |

| limestone | Law | matt, homogeneous, timeless | Worktops, vanity units, floors |

| Gneis | Ticino | hard, brittle, distinctive texture | Stairs, baseboards, kitchens |

| stainless steel | German-speaking Switzerland | hygienic, precise edges possible | Work surfaces, fittings, handrails |

| Brass | Studios in Zurich, Bern | patinated beautifully, warm shiny | Handles, lights, fittings |

| Felt/Wool | Appenzell, Entlebuch | sound-absorbing, temperature-balancing | Acoustic panels, curtains |

| Glass | Glassworks, specialized companies | light-conducting, easy-care | Doors, partitions, display cases |

The art lies in the combination. A calm limestone accentuates the grain of an oak. Brass accentuates the transition between wood and stone with its patina. Textile surfaces break up reverberation without diminishing volume.

Regional manuscripts

Switzerland boasts several interior design dialects, making collaboration with local studios so valuable.

- Alpine region: larch, pine, strong cross-sections, wood joints that remain visible. A sense of security through material thickness and muted surfaces.

- Mittelland: Reduction and precision, finely coordinated joint patterns, integrated technology, restrained color scheme.

- Romandy: Softer tones, smooth transitions between old and new, furniture with elegant edges.

- Ticino: Stone as a stage, cooler light, contrasts between rough texture and smooth metalwork.

Every region has master craftsmen who continue to develop these signature styles—not in a nostalgic way, but in a contemporary way.

From the idea to the finished installation work

A good result starts with a clear process. The process may seem unspectacular, but it saves time, money, and stress.

-

Conversation and spatial analysis

Goals, processes, lighting, acoustics, storage space. The workshop poses questions that often don't fit into a plan. -

Material samples and mockups

Real wood, oiled sample surfaces, edge variations. An A3 mockup on the wall says more than 20 renderings. -

Detailing and tolerances

Joint widths, shadows, adjustment options. Fittings are selected before the wood is cut. -

Prototype and release

Drawers, handles, slatted segments, or connections as functional patterns. Haptics clarifies discussions. -

production

Templates, CNC machining for repeat parts, and handwork for visible surfaces. Surface treatment in multiple steps. -

Assembly and fine calibration

The workshop replicates bearings, hinges, and joints on-site. Only then does it become clear how well-planned the project was.

A tip that's often overlooked: Allow sufficient tolerance to the building structure. Walls are rarely plumb, climate control works, and materials move.

Durability and ecological quality

Craftsmanship is sustainable when it focuses on repairability, regional supply chains, and honest materials. A solid wood kitchen can be re-oiled and re-installed after ten years. A stone floor can be re-sanded. Metal parts are given a second surface instead of being discarded.

Practices that have proven successful:

- Wood from FSC or PEFC sources, ideally with proof of origin from the region

- Air drying or gentle chamber drying for low-stress material

- Oils, soaps, waxes instead of dense synthetic resin layers

- Screw connections instead of adhesive connections in areas subject to high stress

- Easy-to-disassemble design for later adjustments

- Repair-friendly device integration and available spare parts

Durable surfaces are allowed to show their age. Patina isn't a flaw, but rather the history of a room.

Precision meets digital tools

CNC, 3D scanning, and parametric planning are no match for the workbench. They expand the repertoire. Freeform surfaces for a reception desk, millimeter-precise adjustments to existing components, serial parts with consistent quality—all of this can be created faster and more accurately.

The difference is evident in the finish. Edges are rounded by hand, pores are opened or closed, and tones are finely calibrated with pigment oil. The machine sets the foundation, while the hand creates the character.

Smart home elements are integrated invisibly. Ventilation slits form a designed grid, charging stations behind chamfers, lighting channels in shadow gaps. Technology serves the space, not the other way around.

Three projects that make the approach tangible

City apartment in Zurich

A period apartment with stucco and herringbone flooring was given a calm, precise kitchen. Smoked oak fronts, a light Jura limestone countertop, and handles inset with brass recesses. The weight of the stone calms the spatial effect, while the oak grain adds depth. All fronts are screwed from the inside and are adjustable, with the appliances mounted on interchangeable brackets. After two years, the kitchen was oiled, the limestone polished, and finished.

Mountain hut in Graubünden

Stone pine for the bedrooms, brushed larch for the common areas, and wool felt panels on the ceiling. The window reveals are deep and designed with shadow gaps, softening the light. A bench along the south facade accommodates radiators, and the access panels are part of the profiling. The scent of stone pine remains subtle, unperfumed.

Studio office near Lausanne

Open space, concrete floor, lots of glass. Acoustics were the main focus. The solution: framed furniture made of ash with micro-perforated panels and a layer of wool behind them, along with heavy linen curtains. A conference table with integrated connections under a folding solid wood slat. Nothing screams technology; everything works.

Light, color and acoustics

Rooms with a handcrafted essence benefit from carefully planned lighting. The best surfaces lose out when they are flatly lit. A gradation of ambient light, accentuated surfaces, and warm reflections is better.

What matters:

- Mix color temperatures, but use them in a controlled manner. 2700 K in living areas, 3000 K in work areas, and neutral for task lighting.

- Indirect light in shadow gaps creates floating ceilings or light walls.

- Don't illuminate metal surfaces across a wide area. Sidelighting creates depth, while harsh spotlights create glare.

- Consider acoustics from the start. Smaller textile surfaces, perforated panels, and heavy curtains are often sufficient if placed strategically.

Colors reflect the material. Authentic tones provide orientation. Off-white tones next to limestone, gray-green for frames that bear the wood grain. No flashy effects, preferring a consistent rhythm.

Collaboration with studios

The choice of workshop determines the outcome. Good companies openly discuss feasibility and costs, provide references, and invite visitors to their workshop.

Selection criteria:

- References that fit your language, not just pretty photos

- Clean workshop processes, sample culture, test assemblies for complex parts

- Honest advice on budget and deadline

- Tangible material expertise, not just catalog knowledge

- Willingness to cooperate with architect, lighting designer, building services

A typical timeframe for a custom-made kitchen is 8 to 14 weeks from the approval of the detailed plans. Built-in cabinets and small furniture items range between 4 and 10 weeks. Complex projects require a buffer, especially when natural stone and special fittings are involved.

Care, patina and value retention

A well-oiled wooden table becomes more beautiful with use. Water stains can be polished out, and scratches can be smoothed out with a fine sanding. A Jura floor benefits from soap, which closes the pores and keeps the surface matte. Brass handles develop a darker skin that shouldn't be constantly polished away.

Care plan in brief:

- Oiled wood: First aftercare after 6 to 12 months, then as needed. Remove stains immediately with a dry cloth.

- Natural stone: pH-neutral cleaners, soapy water for limestone, check periodic impregnation.

- Metal: Wipe dry, remove fingerprints only selectively, do not use harsh abrasives.

- Textiles: Air regularly, vacuum, and spot clean instead of full wash.

Repairability is part of the plan. Screw connections, accessible fittings, and spare part numbers for hardware systems and devices. This significantly extends the service life.

Structure costs clearly

Quality comes at a price, but transparency builds trust. The biggest cost drivers are material thickness, surface treatment, hardware, and geometric complexity.

A rough guide:

| component | Influences on costs | Notes on optimization |

|---|---|---|

| Carpenter installation | Material thickness, edge pattern, number of fronts | Modular grids, reduced depth variants |

| Kitchen | Appliances, worktop, fittings systems | Set priorities, plan devices interchangeably |

| Natural stone | Origin, thickness, edge processing | Local stones, standardized slab formats |

| Metalwork | Surface, weld seams visible or ground | Reduce visible edges, use series parts |

| Acoustics | Material density, surface area, integration into furniture | Effective positions instead of full disguise |

Those who decide early win. Sample approvals and defined tolerances avoid rework. And where budgets are tight, clear hierarchies help. A beautiful table in the middle of the room can achieve more than ten mediocre components.

Education and knowledge network

Switzerland has a dense network of vocational training centers, universities of applied sciences, and specialized companies. Carpenters, stonemasons, metalworkers, and textile designers work here. Many studios open their doors regularly, some offering small series that can be easily combined.

Inspiration is provided by design museums, regional craft fairs, materials libraries, and trade fairs focusing on quality over quantity. Knowledge circulates quickly, yet the focus remains on substance. Fewer parts, better parts.

Fine details that make the difference

- Shadow gaps on ceilings and bases that visually separate components

- Handle profiles with a pleasant feel instead of visible knobs

- Ventilation solutions that function as design elements

- Hinges with three-dimensional adjustability

- Moving edges that refract light without shining

Such decisions add up to a sense of space that doesn't feel ingratiating. You sense care without being preachy.

Inspiration between Alp and City

A townhouse with old floorboards, a barn with stone walls, a factory hall with exposed beams. Every situation can be transformed with craftsmanship. The key lies in respecting the existing structure and a clear focus on a few strong elements.

A minimalist core also works in historical settings when materials speak at eye level. A stone pine wall in an Art Nouveau room, a Jura ledge in a concrete box, a brass light strip in a wooden room. Contrast with poise instead of sensationalism.

Checklist for getting started

- Formulate goals in one sentence. More storage space, better acoustics, an easy-care kitchen.

- Touch material samples, don't just look at pictures. Test at least two surfaces per material.

- Establish a grid. Consistently define handle heights, front widths, and joint patterns throughout the room.

- Plan lighting early. Outline indirect components and selective accents.

- Request a prototype. Drawer, handle, or edge as a sample.

- Clarify the care issue. Oil, soap, waterproofing with appointments.

- Consider dismantling and disposal. Reuse parts, separate materials.

- Plan for a time buffer. Consider drying times and surface treatment thoroughly.

Spaces built with care give care in return. You set down your cup, and it remains silent. You open a door, and it swings silently. Small moments that carry the everyday. That's precisely where the power of this type of interior lies.